Beam / Column Moment Connection Research

-

Geometric and material nonlinear analysis of moment-resisting connections

-

Slideline surface modelling of contacting members

-

Excellent correlation of experimental testing results

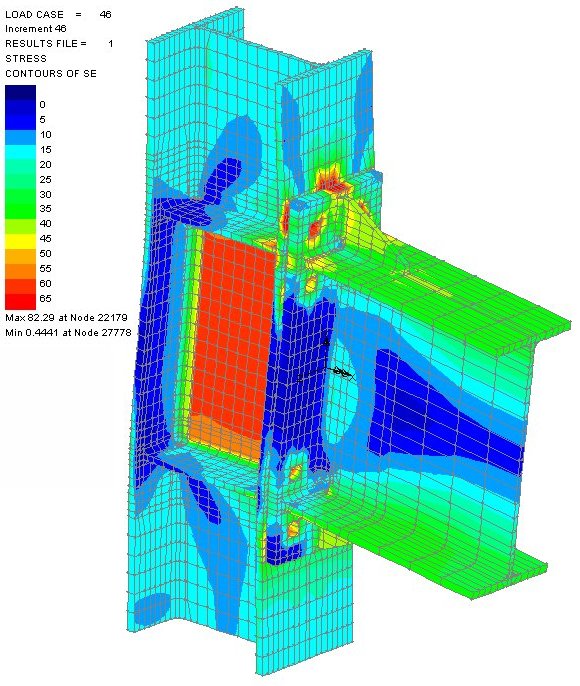

Jon K. Lindsey with HNTB (Kansas City) used LUSAS Civil & Structural to carry out Ph.D. research on alternative moment-resisting connection arrangements. The aim was to make design recommendations that will allow a structural designer to push the limits of the material and connection configuration further and increase the economy of steel moment-resisting frames. By using nonlinear solid modelling with slideline surface contact, excellent correlation was achieved between the results predicted by LUSAS and measurements obtained from experimental testing conducted at the University of Kansas.

Overview

Several different configurations of one particular type of moment-resisting connection – the extended end-plate moment connection – are being researched. These connections typically include wide-flange steel shape sizes and are intended for use in multi-storey structures in moderate to high seismic zones. Both exterior (one-sided) and interior (two-sided, cruciform) connections are undergoing assessment with varying levels of local column reinforcement to investigate weak-column / strong-beam behavior in steel moment-resisting frame 시공.

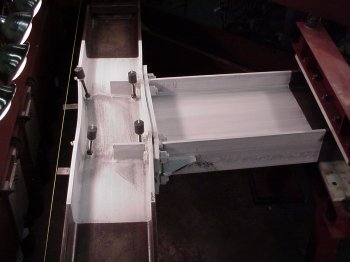

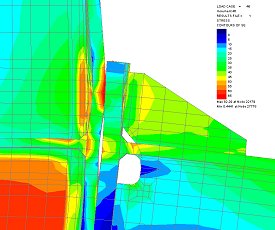

The connection specimens consist of a W21 보 member with a 1″ thick welded end-plate and a W14 기둥 member which is stiffened by a 1/2″ column stiffener (continuity plate) that extends either full-depth or half-depth across the 기둥 web. The 보 and 기둥 sections are bolted together with 1.25″ diameter bolts. The specimens are loaded with a displacement-controlled 하중 history to examine the 응력 and yield in both members. Steel properties for the connections were obtained from coupon tests and subsequently used to define nonlinear material attributes in the LUSAS finite element modelling.

|

|

|

Modelling

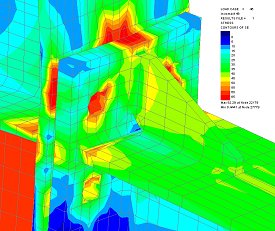

LUSAS was chosen for this research project because of the geometric nonlinear and material nonlinear capabilities it offers for this type of work. Hexahedral 8-noded solid isoparametric elements with enhanced strains modelled the steel members and endplates, and 3D thick nonlinear beam elements were used to model the end-plate bolts. Quadrilateral 4-noded thick shell elements represented the steel members away from the area of interest. This modelling approach allows a high concentration of 3D elements to be used where needed and correctly models the actual lengths of each member to allow for the replication of the actual testing system end-constraints and the application of the applied displacement. In all, around 8000 elements modelled each 보 and 기둥 connection. The aim of the modelling was to correlate the experimental data, and to do so it was essential, due to the nature of the extended end-plate moment connection under investigation, that the 기둥 and 보 components could deform independently of one another to capture the true behavior of the connection interface. Correct modelling of the column flanges and contacting end plates is the key to analyses of this type. To accurately model each connection and mimic the applied experimental loading, each LUSAS model incorporated slideline surfaces to represent the contacting members. LUSAS slidelines automatically take care of any frictional contact between contacting components and allow complex problems involving contact and friction to be modelled and analysed with relative ease.

Loading and Supports

Loading was applied using displacement-controlled 하중 curves – a means of loading each connection model by applying a predefined increasing displacement to the end of the 보 member. These displacement parameters were based on prescribed inter-storey drift increments. The single-cycle 하중 curve was proportioned such that the model would experience “significant” yielding at the peak displacements of the cycle. Model support conditions replicated those of the experimental testing apparatus.

Results

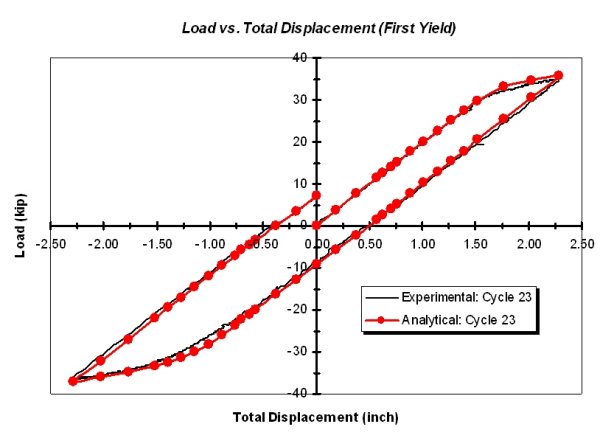

From the 3D solid, material and geometric nonlinear 하중 curve analysis, the first yield cycle (where significant yielding is exhibited), as observed and recorded in the experimental testing, was recreated exactly in the LUSAS analysis.

Jon K. Lindsey, Structural Engineer at HNTB (Kansas City) said: “The LUSAS analysis matched the experimental results very, very closely and was much better than I expected. This was primarily due to using accurate material data obtained by material testing to define the elasto/plastic material model for LUSAS to use, and also due to having defined all the model geometry – the fillet welds, the weld-access holes, fillets of wide-flange sections, the clips on stiffeners, etc. exactly as per the test models.” He continues: “The LUSAS slideline facility was especially useful to me for this work as, also, was the ability to quickly modify the LUSAS model for the different connection types required. Using LUSAS I could graph nearly any aspect of the results against any other aspect and create high-quality charts, contour plots and animations not just for ‘eye candy’, but as learning tools and to gain valuable insight into the structural behaviour.”

응력 time histories were plotted to chart the formation of 응력 concentration zones and areas of yield could be easily seen. 하중 versus total displacement and time history data was graphed to record the correlation of the experimental results.

|

|

|

|

Recommendations and Future Work

As a result of this work, it is intended that design recommendations will be given to allow structural designers to push the limits of the material and connection configuration further and increase the economy of the steel moment-resisting frame. LUSAS will also be used on more investigations of proposed configuration changes to conventional column-side details.

“The LUSAS analysis matched the experimental results very, very closely and was much better than I expected. Using LUSAS I could graph nearly any aspect of the results against any other aspect and create high-quality charts, contour plots, and animations not just for ‘eye candy’ but as learning tools and to gain valuable insight into the structural behaviour.”

Jon K. Lindsey, HNTB (Kansas City)